Washington State University

Research Assistant, January 2017 - May 2017

I assisted Dr. Arda Gozen at Washington State University to advance soft matter electronics within the medical and consumer wearable industries. The goal of this research was to eventually 3D print flexible electronics. The project was great experience in following scientific procedures through trial and error; create test samples, test, analyze data, modify and repeat. Within this project I used my SolidWorks skills, enhanced my materials background, and used new equipment.

Making the Samples

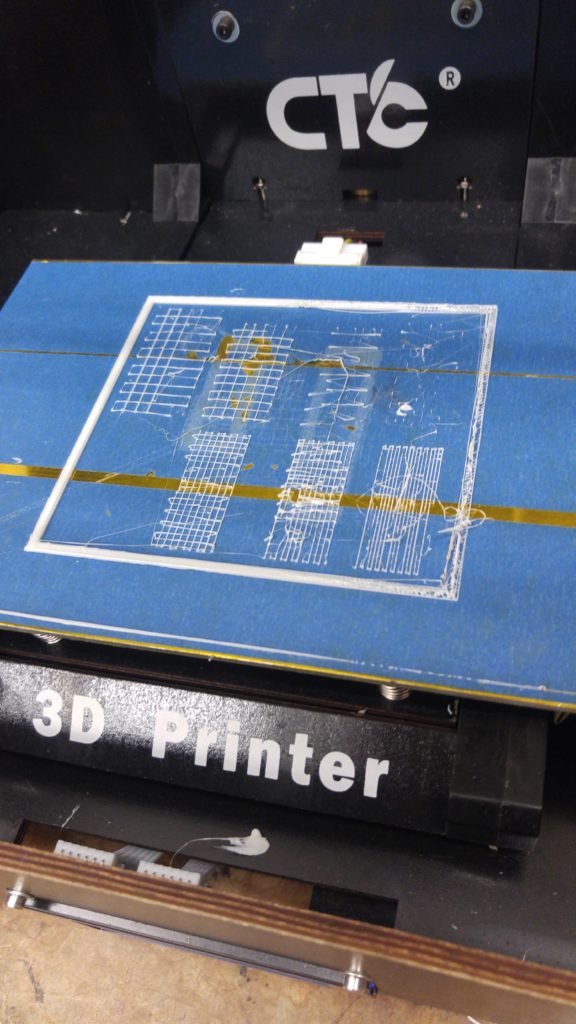

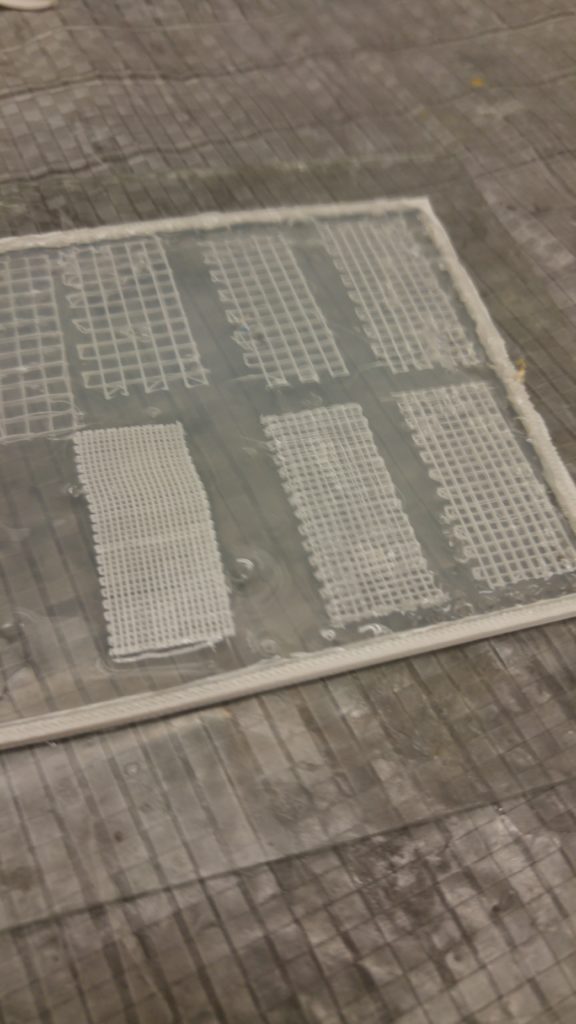

The samples I designed were composed of two parts. The first being an internal structure that was 3 printed from different plastics. The second being a solid filler that was more of a rubber like material. I used SolidWorks and a Makerbot clone 3D printer to create different structures to test. After printing the structures, I’d fill them with the secondary solution and using a vacuum chamber.

Testing

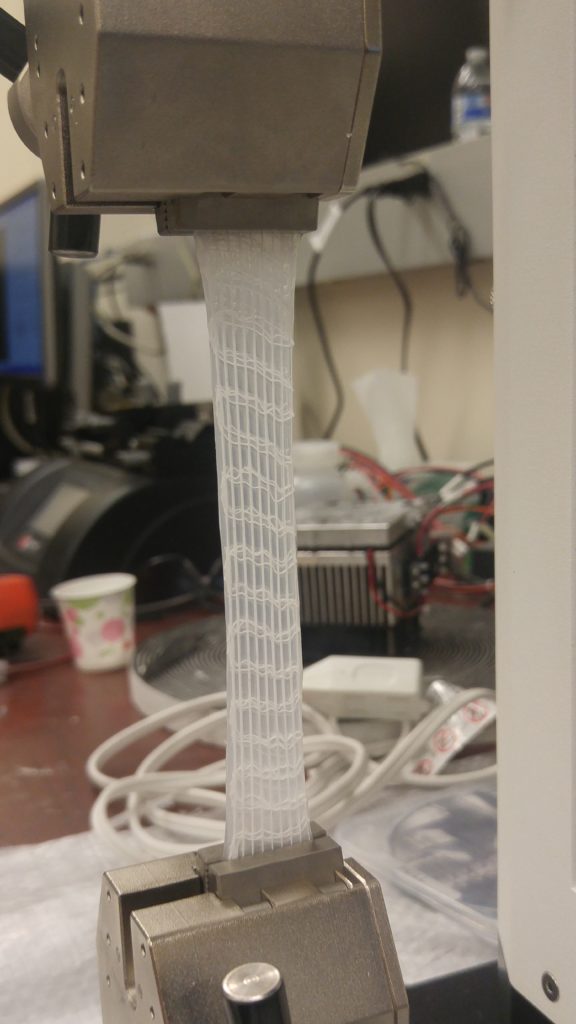

After creating a batch of samples I used a Mark10 tensile machine to collect stress/strain data and tested each sample until failure. This was my first experience using a tensile machine, it was great to have that experience going into my laboratory courses later.

Analyzing the data

The tensile machine generated excel files for me recording the elongation and force throughout each test. Using that data I was able to create stress strain curves and determine material properties.

This was a fun research to be a part of, unfortunately my course loads became more difficult and I was only able to dedicate 1 semester’s worth of time to it, if I had more free time I would have loved to continue this research.